Rough Diamond Ore Processing and Treatment

Several techniques are used to process the diamantiferous ore. The techniques used will not be the same between artisanal and industrial mining, however there are some common elements:

- Crushing, not too fine (rough diamond must not be crushed).

- Screening separates the sand from large elements.

- Washing disaggregates muds from ore.

- Concentrating process: rotary mixers, agitators, jigs, cyclones, cones, heavy-media separators (industrial mining only) are used to achieve density separations.

- Collecting diamond process is done using grease table or x-ray separators. Final separation and sorting is done visually.

Artisanal Diamond Mining

The material for this type of mining is very rudimentary: shovel, picks, sieves, pumps, etc...

It is the will and the courage which is significant for the miner.

It is the form of diamond mining which employs the most labour.

Semi-Industrial Diamond Mining

Mobile Diamond Washing Plant

A mobile diamond washing plant can be a judicious choice, it is autonomous and it can be moved from a place to another.

Dredge

Depending on the hardness of the bottom floor, it allows an average extraction of 7 to 10 cubic meters per hour of stelled gravels to a depth of 10 meters. Density separation up to 91% heavy materials above 80 micromilimeters are collected.

Diamond Washing Plant (Fixed or Semi-Mobile)

The capacity of these washing plants is definitely higher than mobile washing plant.

Their capacity varies between 15 m3/h to 200 m3/h. They can be entirely automated, and so there is no direct contact with diamonds.

All washing plants are customed.

Soditra-Sodiloc company provides and installes the Hymex diamond washing plant in Guinea (capacity 160 m3/h).

Industrial Diamond Mining

The costs to be considered for this type of mining are considerably higher than the two other types of mining.

Several parameters are essential: negotiations with the authorities, systematic study of the deposit (shape, dimensions, nature of the ground and the subsoil), study of the climatic conditions, provisioning of water and electricity, construction of roads, creation of schools and hospitals, etc...

We can say to finish that it is the nature of the deposit which defines the mode of mining.

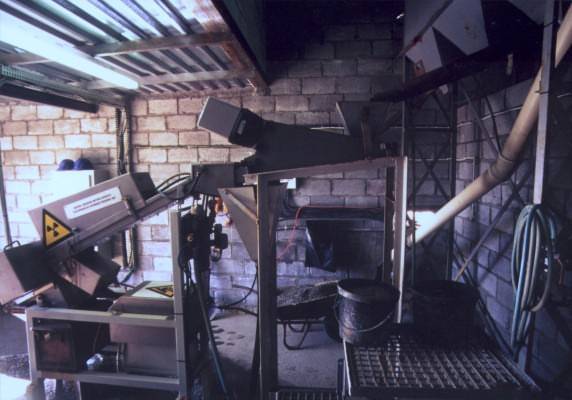

For this type of mining the operations of diamond collecting are automated, they use a x-ray separator. You can find below a diagram and an image (click to enlarge images).